Tech Tip - Why Am I Seeing Acetone in My Performance Monitoring?

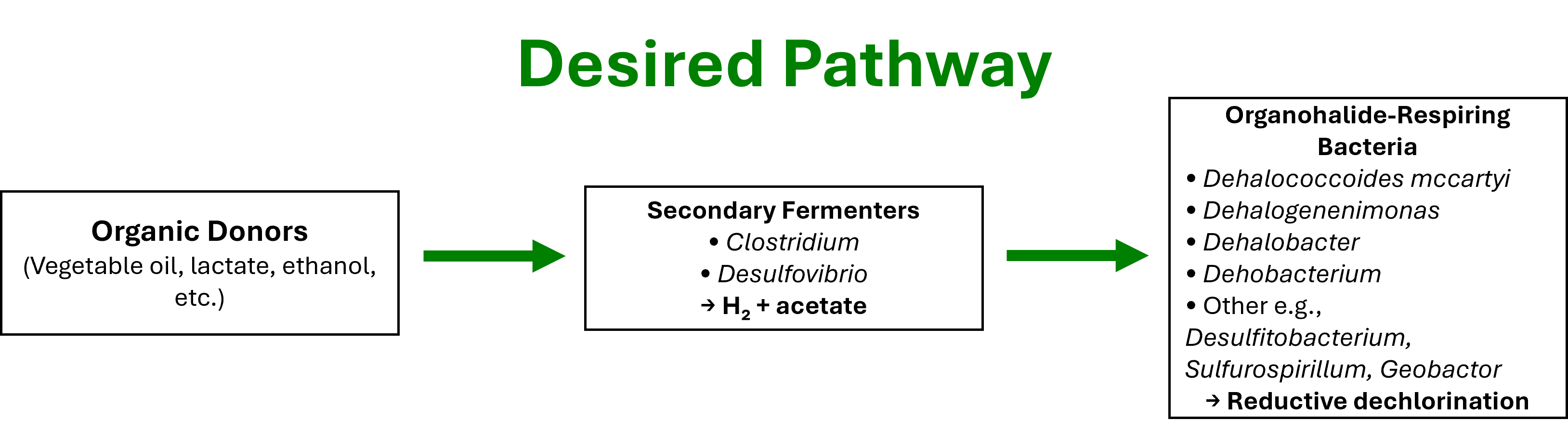

If you’ve ever reviewed groundwater performance data for a reductive dechlorination project and noticed acetone, you’re not alone. While not a typical monitoring target, acetone can show up under certain biogeochemical conditions, and its appearance tells us something important about what’s happening underground.

Why Acetone Appears

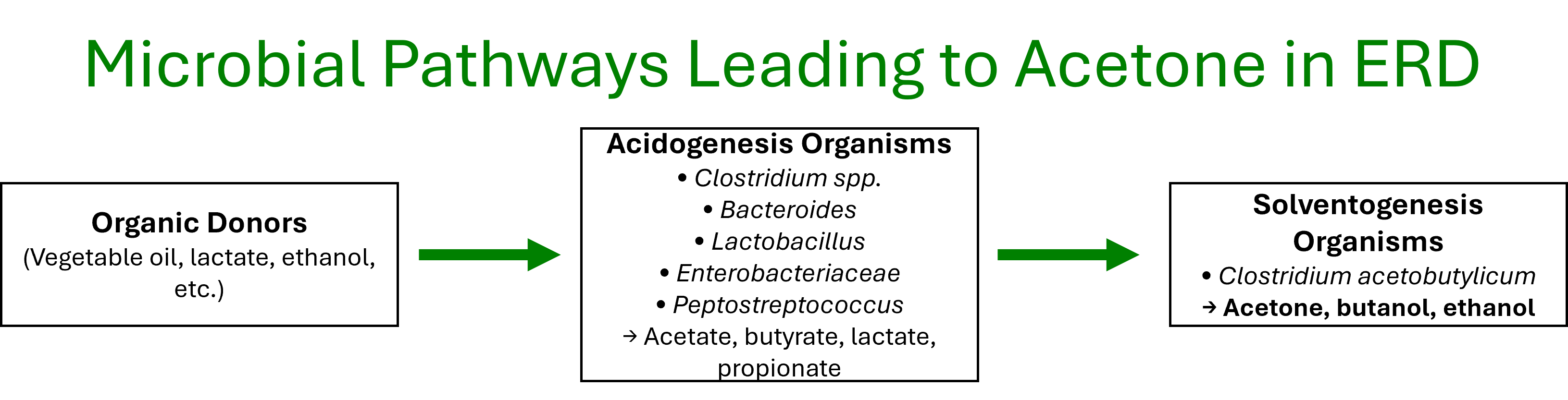

Acetone production is strongly influenced by the microbial community composition. Certain solventogenic bacteria, particularly Clostridium acetobutylicum, naturally produce acetone through acetone–butanol–ethanol (ABE) fermentation. This process has two phases:

- Acidogenesis – cells generate organic acids (acetate, butyrate).

- Solventogenesis – as pH declines, metabolism shifts to producing neutral solvents like acetone, butanol, and ethanol.

At the biochemical level, acetone is formed by the decarboxylation of acetoacetate, catalyzed by the enzyme acetoacetate decarboxylase.

In aquifer remediation systems, this shift often occurs when microbes face nutrient imbalance. If carbon is abundant but nitrogen, phosphorus, or trace metals are limited, microbial growth is constrained. The excess carbon is redirected into solventogenic pathways, leading to detectable acetone in monitoring wells.

What Happens Over Time?

Fortunately, acetone is not usually persistent. Other microbial groups—such as methanogens and acetogens—can degrade acetone further. However, if nutrient limitation is chronic, acetone can cycle back or accumulate at sustained levels.

A Useful Rule of Thumb

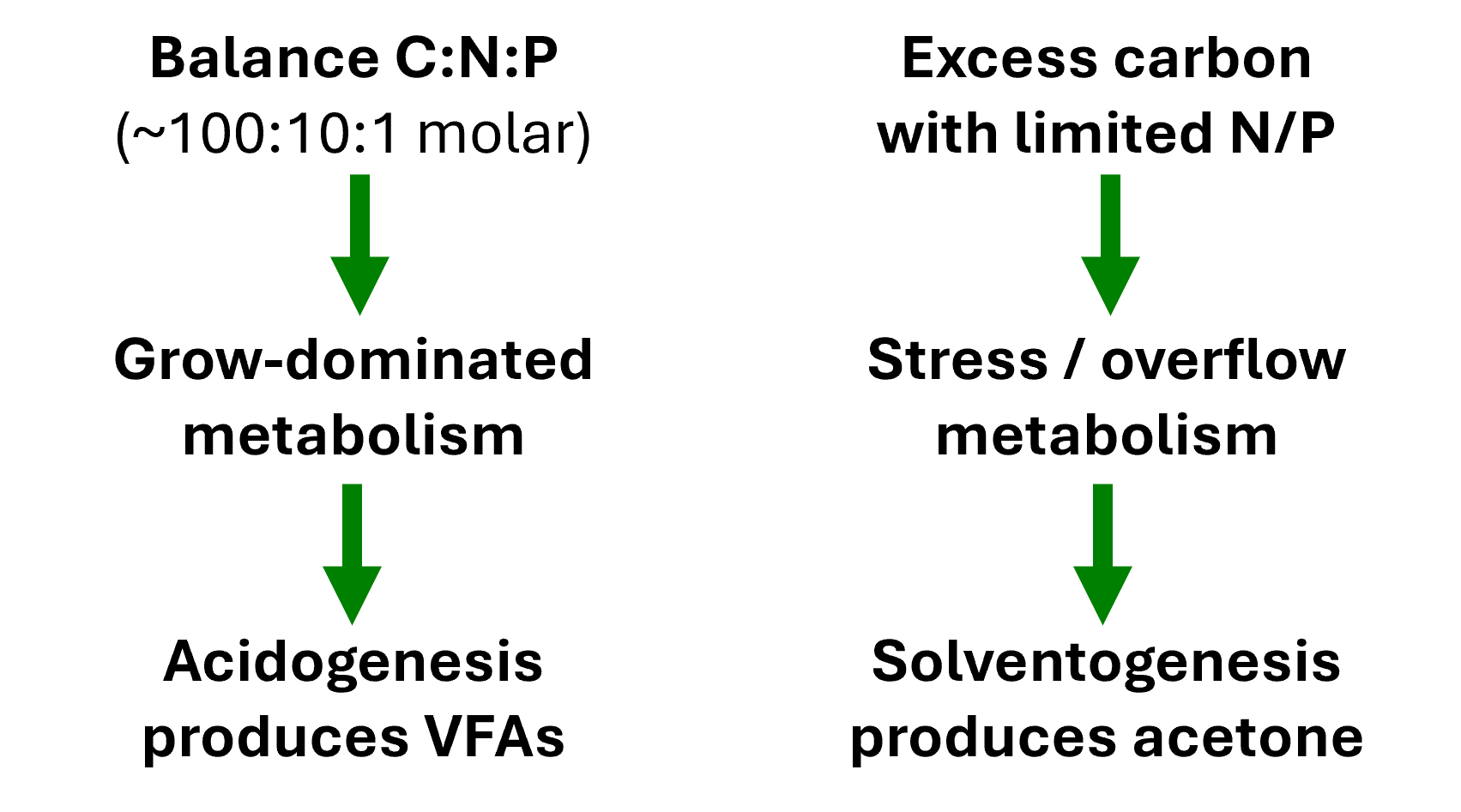

Microbial metabolism follows predictable patterns depending on nutrient balance:

- Balanced C:N:P (~100:10:1 molar) → growth-dominated metabolism. Fermenters channel carbon into acidogenesis, producing volatile fatty acids (VFAs) like acetate and butyrate to support new cell biomass. Acetone and other solvents are minimized.

- Excess carbon with limited N/P → stress or overflow metabolism. Growth is constrained, and cells shift into solventogenesis, producing acetone, butanol, and ethanol as carbon overflow products.

The Tersus Approach

The appearance of acetone in the field is often a clear sign of nutrient imbalance. Unlock faster, cleaner remediation results and avoid costly setbacks with the right nutrient solution for every project. TersOx™ Nutrients-QR powers ERD systems with instantly available nutrients for robust dechlorination, while BioBoost™ GeoChem accelerates in situ biogeochemical transformation and supports balanced nutrient delivery.

- Fast-acting, soluble nutrient blend tailored for bioremediation

- Provides nitrogen, phosphorus, potassium, and microbial growth enhancers

- Supplies exogenous nitrogen source (NH4⁺)

Beyond alleviating nutrient stress, nutrient addition also accelerates dechlorination. Kaya et al. (Environ. Sci. Technol. 2019, 53, 24, 14548–14558) showed that adding an exogenous nitrogen source (NH4⁺) increased cis-1,2-dichloroethene (cDCE) to ethene dechlorination rates by roughly fivefold. This underscores how a balanced amendment strategy not only supports healthier microbial metabolism but also drives faster, more reliable contaminant cleanup.

Key Takeaway

Seeing acetone in your monitoring isn’t a setback; it signals nutrient stress in your microbes. With the right balance of carbon, nitrogen, and phosphorus, you can redirect metabolism from unwanted solvent production toward efficient dechlorination. Keep your injection program running at peak efficiency and see measurable progress toward closure with TersOx™ Nutrients-QR and BioBoost™ GeoChem.

👉 Contact us to discuss how TersOx™ Nutrients-QR or BioBoost™ GeoChem can be integrated into your next project and help you achieve more consistent remediation results.